Leingarten, August 2024 - Körber is implementing the complex automation and integration of Beiersdorf’s new distribution center in Leipzig. From there, the skin care group will set new standards in logistics efficiency and value-added services.

Beiersdorf is currently building a state-of-the-art logistics hub as the largest distribution center in the company's supply chain network in the immediate vicinity of its production site in Leipzig, which will open in 2023.

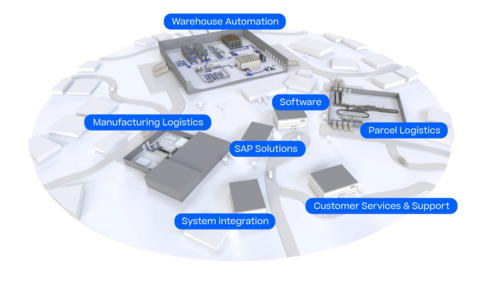

As a logistics general contractor, solution provider and system integrator, Körber is implementing a wide range of automation technologies in the facility, including conveyor and picking technology, and integrating them into a powerful, efficient overall system via a complex ERP environment. “As a central European hub, the new distribution center is the blueprint for the efficient and sustainable logistics of tomorrow - and for future-oriented interaction between automation technology and manual activities,” says Andreas Ebert, CEO Automation, Körber Business Area Supply Chain.

At the heart of the facility is an 18-aisle high-bay warehouse for approx. 125,000 pallet spaces for the supply and disposal of two fully automated layer palletizing systems. The pallets will be transported via an electric floor conveyor with 68 vehicles. For container logistics, a multi-aisle, likewise fully automated shuttle AS/RS in conjunction with a highly dynamic container picking system is planned. The incoming goods, picking, packaging and value-added services (VAS) areas will also be largely automated and intelligently integrated into the process chain with the manual activities. Körber is implementing a comprehensive end-to-end solution that goes beyond pure warehouse technology to ensure optimum interaction between all processes. Körber is implementing an SAP-based system landscape that is specially tailored to customer requirements. The seamlessly integrated EWM, TM, YL, BN4L and PM modules serve to optimize adjacent processes in warehouse, transport, yard and maintenance management as well as smooth interaction with service providers.